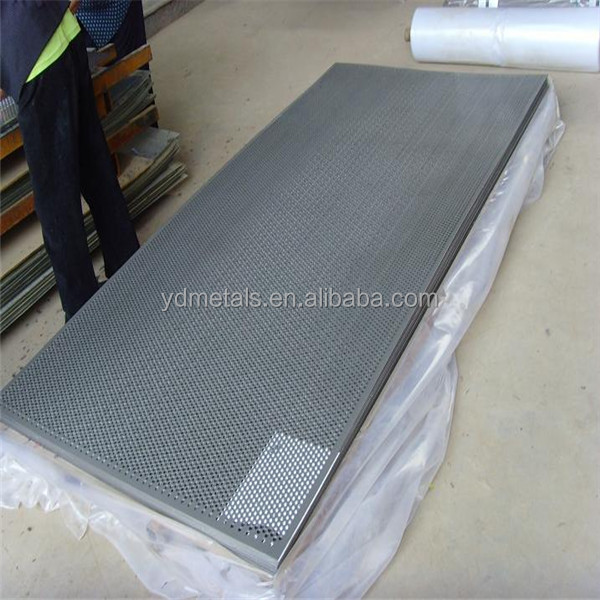

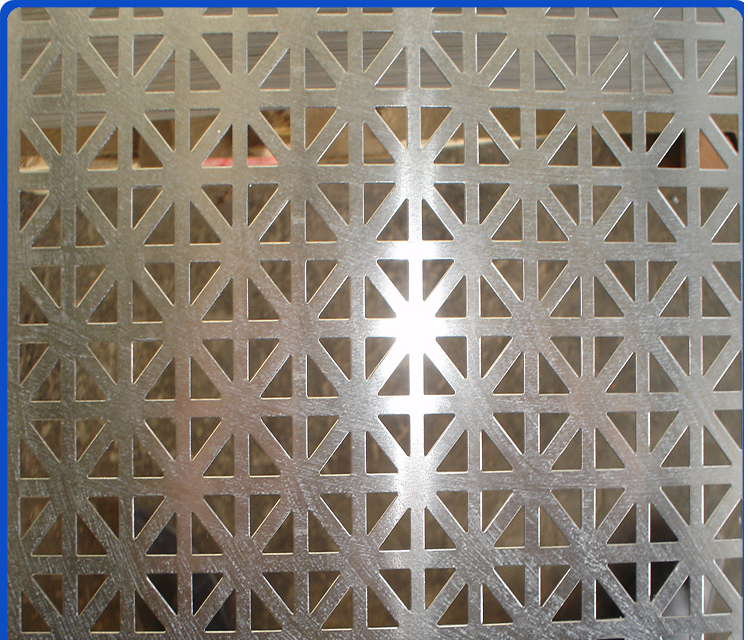

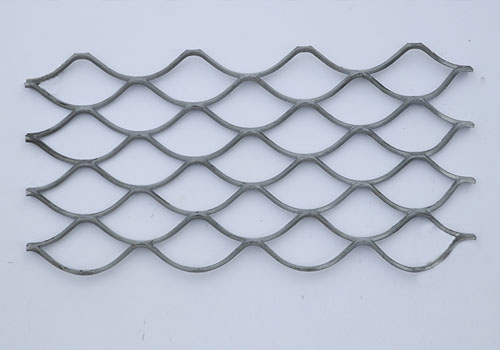

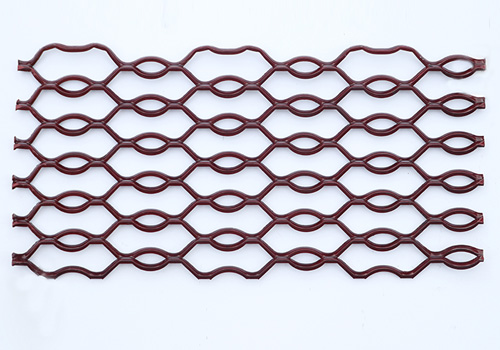

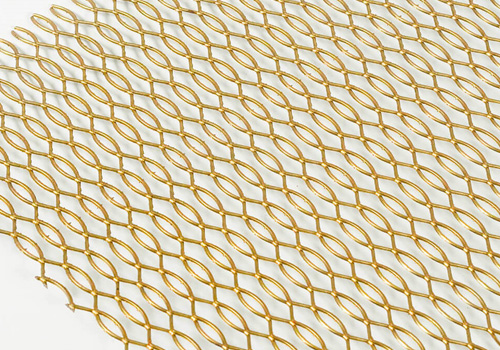

Insimbi eyenziwe ngopende inika isisombululo sezinkampani ezimbonini eziningi. Imikhiqizo yensimbi eyenziwe ngopende yenziwa kusetshenziswa izibhakela noma imishini ekhiqiza izikhala, imigoqo, izimbobo noma amanye amaphethini ensimbi. Ukugcotshwa kungenziwa ngenhloso yokusebenza, njengokwenza umkhiqizo uvumelane nezidingo zomsebenzi womkhiqizi, noma ukuthuthukisa ukubonakala komkhiqizo ophelile. Insimbi yethu ebunjiwe ihlukahluka futhi isebenza kuzo zonke izinhlelo zokusebenza zokwakha. Abasebenzi bethu abanolwazi bangasebenzisa amapulani akho ukwenza ukuphrinta okususwayo ukusiza kuphrojekthi yakho.

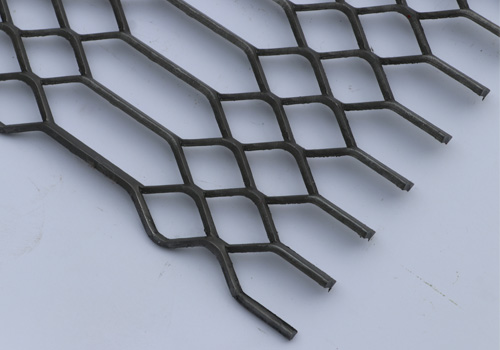

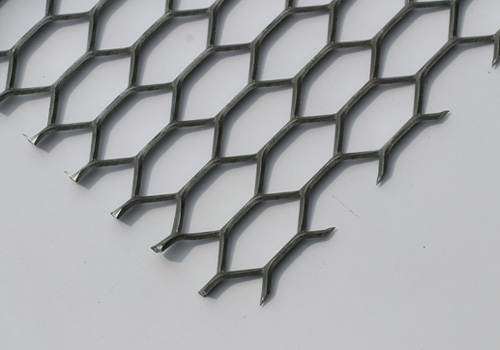

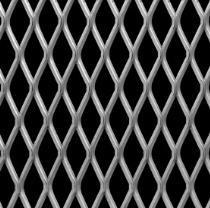

IMIPHATHA YEMIGODI ETHENGISA KAKHULU

E062 / 125 22% indawo yamahhala

E062 / 125 22% indawo yamahhala E078 / 137 29% indawo yamahhala

E078 / 137 29% indawo yamahhala E093 / 157 32% indawo yamahhala

E093 / 157 32% indawo yamahhala E093 / 250 13% indawo yamahhala

E093 / 250 13% indawo yamahhala E098 / 157 35% indawo yamahhala

E098 / 157 35% indawo yamahhala E118 / 196 33% indawo yamahhala

E118 / 196 33% indawo yamahhala E125 / 250 23% indawo yamahhala

E125 / 250 23% indawo yamahhala E125 / 250 23% indawo yamahhala

E125 / 250 23% indawo yamahhala E157 / 187 64% indawo yamahhala

E157 / 187 64% indawo yamahhala E157 / 250 36% indawo yamahhala

E157 / 250 36% indawo yamahhala E187 / 250 51% indawo yamahhala

E187 / 250 51% indawo yamahhala E196 / 275 46% indawo yamahhala

E196 / 275 46% indawo yamahhalaifomethi-Usayizi mm 1000 × 2000

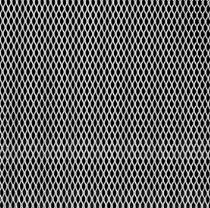

| Imbobo | o / a | insimbi yekhabhoni | insimbi engagqwali SS304 | i-aluminium | steel lashukumisa | ||||||||||||||||

| UBUKHULU | |||||||||||||||||||||

| R | T | % | 1 | 1.5 | 2 | 3 | 0.4 | 0.5 | 0.8 | 1 | 1.5 | 2 | 3 | 1 | 1.5 | 2 | 0.5 | 0.8 | 1 | 1.5 | 2 |

| 0.4 | 1.5 | 6% | ● | ||||||||||||||||||

| 0.5 | 1.5 | 10% | ● | ||||||||||||||||||

| 0.6 | 1.5 | 15% | ● | ||||||||||||||||||

| 0.8 | 1.8 | 19% | ● | ● | |||||||||||||||||

| 0.8 | 2 | 15% | ● | ||||||||||||||||||

| 1 | 2 | 23% | ● | ● | ● | ● | ● | ||||||||||||||

| 1 | 2.2 | 19% | ● | ||||||||||||||||||

| 1.5 | 2.5 | 33% | ● | ● | ● | ● | |||||||||||||||

| 1.5 | 3 | 23% | ● | ● | ● | ||||||||||||||||

| 2 | 3.5 | 30% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2 | 3.6 | 28% | ● | ||||||||||||||||||

| 2 | 4 | 23% | ● | ● | ● | ||||||||||||||||

| 2 | 4.5 | 18% | |||||||||||||||||||

| 3 | 5 | 33% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |

| 3 | 6 | 23% | ● | ● | |||||||||||||||||

| 4 | 6 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| 4 | 7 | 30% | ● | ● | ● | ||||||||||||||||

| 5 | 7 | 46% | |||||||||||||||||||

| 5 | 8 | 35% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| 6 | 9 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 8 | 12 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| 10 | 15 | 40% | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

R = ububanzi bezimbobo eziyindilinga

I-T = hole pitch, staggeres ku-60%

ISICELO

- Amabhentshi angaphandle nangaphakathi

- Obhasikidi nemigqomo kadoti

- Izikrini nezigubhu

- Izakhi zokwakha

- Abakhipha uthuli

- Izihlungi zomoya namafutha

- Ama-mufflers namapayipi wokukhipha

- Ifenisha yasengadini

- Amapaneli ophahla wamanga

- Izikrini zokukhanyisa

- Imisakazo kanye nama-radar

- Iziqandisi

- Ama-grills omoya

- Okomisa okusanhlamvu nokuhlunga

- Izinhlelo ze-Acoustic

- Izithelo crushers

IZizathu EZIYINHLOKO ZOKUKHETHA

- Ukubukeka okuhehayo nempilo ende yokusebenza.

- Ukubukeka okuhehayo nempilo ende yokusebenza.

- Okungenisa umoya futhi okuphefumula.

- Ngokwemvelo ilula futhi kulula ukusebenza nayo.

- Umphumela wokunciphisa umsindo.

- Non-kazibuthe, anti-ukugqwala.

- Amasayizi emigodi ahlukahlukene, ubujamo, amaphethini atholakalayo.

- Akuphoqelekile aluminium ipuleti ukushuba.